General Role: project coordination while working at SPF.

Specific technologies in charge of: ice slurry development using the supercooling method.

Main goal of the project: The overall goal of the Slurry-Store project was to experimentally investigate ice storages able to store and melt slurries without using a stirring device. The specific objectives of the project were: i) to design, construct and test an ice slurry storage tank capable of achieving 50 % ice mass fraction (ice packing factor), ii) to develop, construct and test an ice crystallizer for stable continuous ice slurry production of 6 hours, iii) to design, construct and test concepts for loading (icing) and unloading (melting) and iv) to develop a mathematical model for the ice slurry storage and validated it with experimental data.

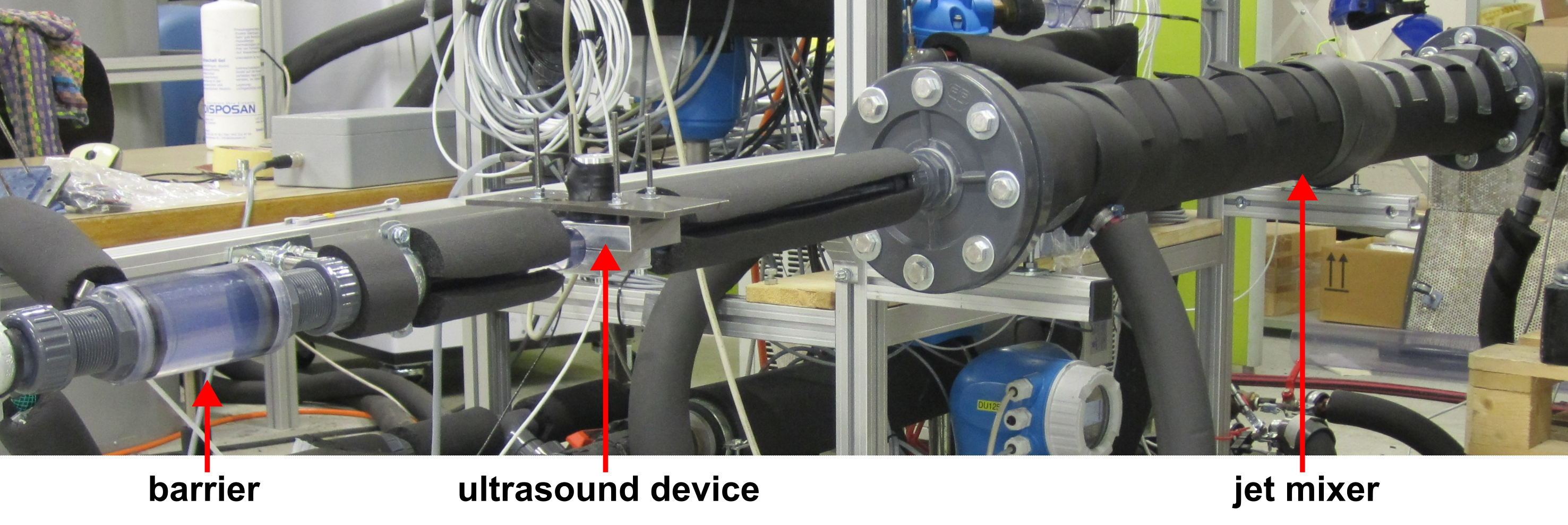

Summary of Final Results: In the Slurry-Store project, a method to produce ice from pure supercooled water in a closed, continuously operating system was conceived, designed, fabricated and tested. The entire ice slurry system consisted of an ice slurry storage tank, a pump to convey the supercooled liquid water and subsequently generated slurry, a preheater, in line filter and a static mixer to remove remaining solid impurities and ice crystals in the tank outlet; a supercooling heat exchanger (”supercooler”) and a flow-based crystallizer that is responsible for converting the supercooled water into a fluidized ice slurry.

Most of these parts were adapted and adjusted over multiple iterations. In a first design, a continuous production of ice for more than 24 hours and up to 70 kg of ice was demonstrated, resulting in a solid mass fraction (ice packing factor ) of 12 % in the storage tank, a crystallizer efficiency of 60 % and a crystallizer power of 560 W. Using the second generation of jet mixers in the crystallizer resulted in increasing the crystallization power up to 1700 W with a crystallization efficiency of 77 %. In the second experimental campaign, the bottle neck was the thermal barrier. Resolving this limitation, it is conceivable that the current jet mixer would allow for higher crystallization power output. The current state of knowledge of the flow-based crystallizer for supercooled water includes the identification of individual strategies that are effective to inhibit upstream ice propagation, initiate controlled nucleation, and promote ice-slurry fluidization post-crystallizer. Thus, the overall concept incorporates three components that are strongly interdependent. A failure in one of the three components results in breakdown of the overall ice slurry process, making it essential that all three components are treated cohesively as a single mechanism. This unit must ensure a complete consumption/release of the supercooling potential to produce pumpable ice slurry. The required residence time within this device and thereby its volume can be reduced by increasing the internal rates of heat and mass transfer (via turbulent mixing) and by increasing the population of available nuclei to propagate crystallization. However, more research is needed to further reduce the flow-based crystallizer’s energy consumption (i.e., internal heat gains reducing nucleation yield), increase the thermal power from crystallization and enhance its tolerance to varied operation conditions.

It was shown that the complete system was able to supercool water by more than 3 K for short duration and by 2 K in steady state for more than 24 hours while producing ice slurry when all the devices and components that have been described herein are present and functioning. It was found that supercooling operation at 3 K challenged the stable operation of the flow-based ice crystallizer system rather than the supercooler.

Multiple tank inlet configurations have been evaluated with the aim to increase the ice packing factor and improve two-phase stratification in the ice storage tank. Also, methods have been tested to limit entrained ice crystals in the piping from the tank to the supercooler. For very low fluid flow velocities, the slurries stratify at the top of the piping system. Thus, classical tank stratification guideline using low fluid velocities at the the port inlet can not be used here due to contradicting ice slurry transportation limitations. Furthermore, tank inlets should be placed in such a way that ice is pushed away from tank outlets to prevent ice from re-entering the closed loop circulation of water. The throw distance, a ratio of outlet velocity and the distance to the next tank wall should be strongly considered during tank design. Different approaches to melt the ice stored in the tank via direct contact heat exchange have been tested, using flow rates between 400 kg/h to 2000 kg/h resulting in peak melting powers ranging from 8 kW to 14 kW. Flow velocities, inlet, outlet and water temperatures at five different heights within the tank were measured during melting. This data was used to successfully validate an ice slurry storage numerical model.

Duration: 2022-2024

Final Report: https://zenodo.org/records/13767102

Web: https://www.aramis.admin.ch/Grunddaten/?ProjectID=47202

Work conducted at: Insitute for Solar Technology (SPF)

Funding Agency: Swiss Federal Office Of Energy (SFOE)